With the continuous advancement of technology, sensors are being used more widely in various fields, whether it's in smart homes, industrial automation, medical devices, or environmental monitoring, sensors play an indispensable role. As one of the core components of sensing equipment, the performance and reliability of sensor connectors directly affect the stability and accuracy of the entire sensing system. In this article, we will explore the significant applications of sensor connectors in sensing devices and their role in driving future technological development.

I. Basic Overview of Sensor Connectors

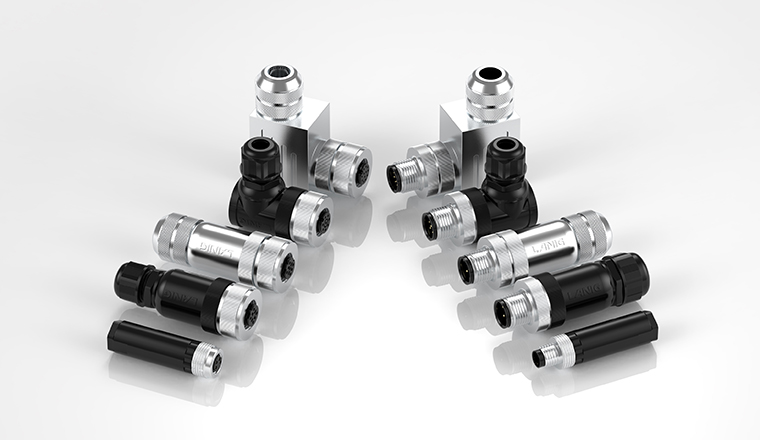

A sensor connector is an electrical interface used to connect sensors to other devices or systems, primarily responsible for signal transmission and power supply. Depending on the application scenario, the types and specifications of sensor connectors vary. Common types of sensor connectors include circular connectors, rectangular connectors, board-to-board connectors, and coaxial connectors.

The choice of connector depends on various factors, such as the type of signal (analog or digital), transmission speed, environmental conditions (such as temperature, humidity, vibration, etc.), and specific application requirements (such as waterproof, dustproof, corrosion resistance, etc.). These factors determine the design of the connector and the selection of materials.

II. Applications of Sensor Connectors in Various Fields

Industrial Automation

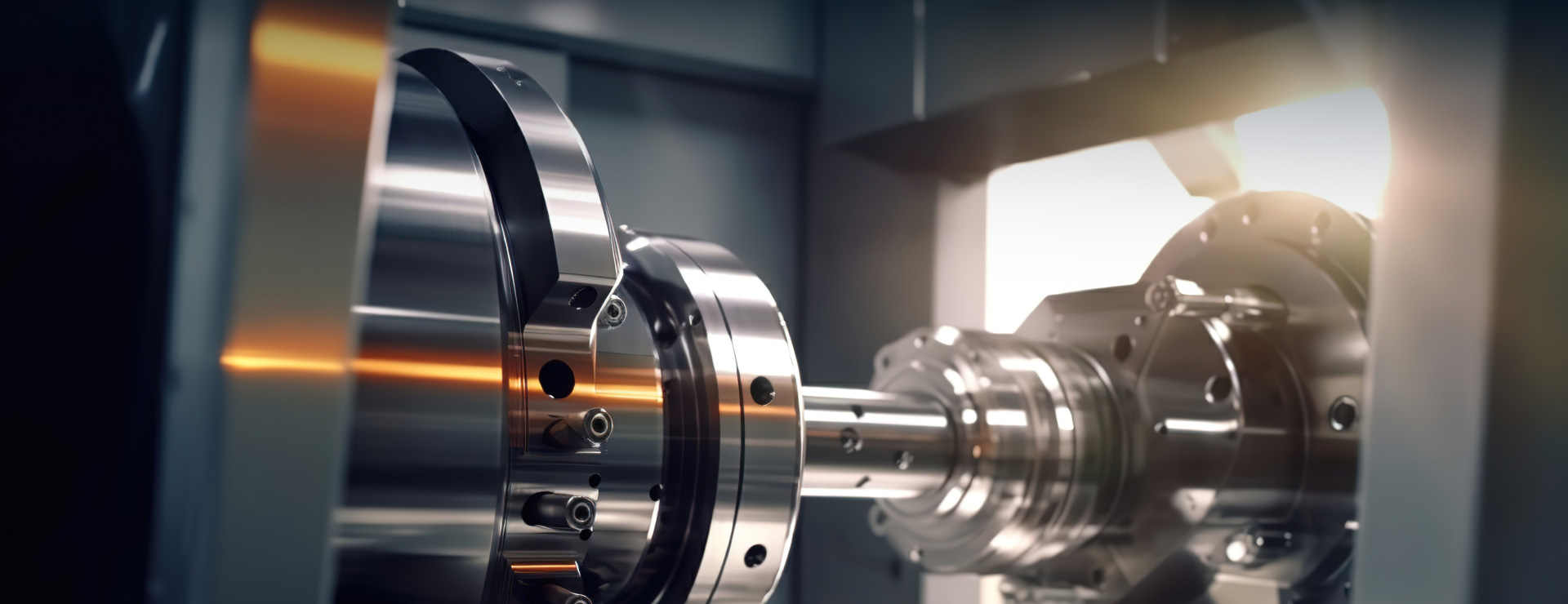

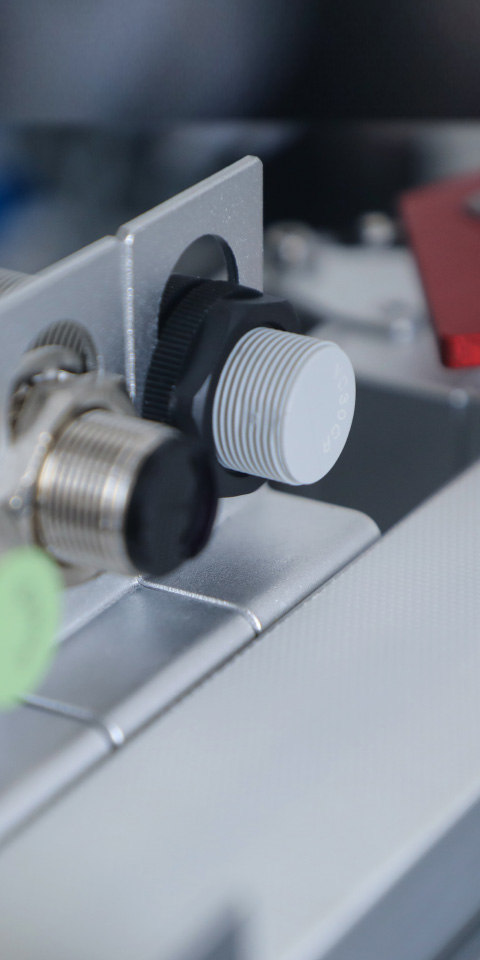

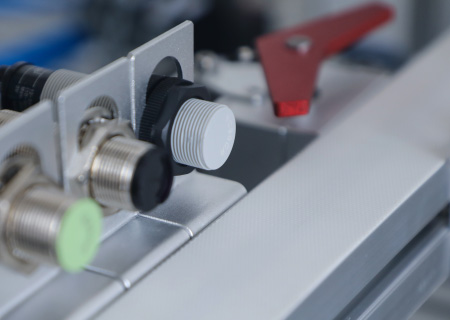

In the field of industrial automation, sensors are widely used for robot motion control, quality inspection on production lines, and equipment fault diagnosis. The industrial environment is often harsh, demanding high durability and stability from sensor connectors. For instance, in high-temperature, high-pressure, and high-vibration environments, connectors must ensure stable signal transmission and have good anti-interference capabilities. Specific circular connectors and rectangular connectors are commonly chosen for their robust structures and reliable locking mechanisms.

Automotive Electronics

With the rise of smart cars and autonomous driving technology, sensors have become increasingly important in automotive electronics. From basic temperature sensors and pressure sensors to complex lidar and camera systems, there is a variety of sensors and complex layouts. Automotive electronics require connectors to have waterproof, dustproof, and vibration-resistant characteristics to cope with the complexity of the vehicle environment. Especially in high-speed moving scenarios, connectors need to provide stable signal connections to ensure the real-time transmission and accuracy of data.

Medical Devices

In the medical field, sensors are used to monitor vital signs such as heart rate, blood oxygen, and blood pressure. Sensor connectors in medical devices require extremely high reliability and accuracy, as well as meeting medical-grade safety and hygiene standards. For example, connectors with excellent conductive properties and corrosion resistance are widely used in biosignal sensors, effectively ensuring the clear transmission of signals without interference from the external environment.

Environmental Monitoring

In environmental monitoring, sensors are used to detect air quality, water quality, soil moisture, temperature, and other parameters. The requirements for sensor connectors mainly focus on weather resistance and stability, as monitoring equipment is often exposed to the elements and needs to withstand various extreme weather conditions. Therefore, environmental monitoring sensor connectors usually feature waterproof, dustproof designs and are made of corrosion-resistant materials to extend the lifespan of the equipment.

III. Development Trends of Sensor Connector Technology

With the development of the Internet of Things (IoT), artificial intelligence (AI), and big data analytics technology, the demand for sensors and their connectors is showing several trends:

Miniaturization and High Integration

To adapt to the trend of miniaturized devices, sensor connectors are evolving towards smaller, lighter, and more integrated designs. Miniaturized and multi-functional connectors can provide a variety of interface options within limited space, meeting diverse application requirements.

High Reliability and Environmental Resistance

In the future, as sensors are increasingly applied in more adverse environments, connectors will need to offer higher reliability and environmental resistance. The application of new materials and processes will enable connectors to have stronger resistance to high temperatures, corrosion, and water resistance.

Intelligence and Networking

In intelligent and networked applications, sensor connectors need to support high-speed data transmission and networked management. For example, connectors that support Ethernet protocols can realize remote monitoring of devices and real-time data transmission, thereby enhancing the overall intelligence level of the system.

Sensor connectors, as key components of sensing equipment, directly affect the performance and application effects of the sensing system. With the development of sensing technology and the continuous expansion of application scenarios, sensor connector technology is also advancing. In the future, with the emergence of higher-performance, more reliable, and more intelligent sensor connectors, the application of sensing devices will be more extensive, helping various industries achieve intelligentization and efficiency.

The registered trademark belongs to Lanig Electric (Zhejiang) Co., Ltd

The registered trademark belongs to Lanig Electric (Zhejiang) Co., Ltd