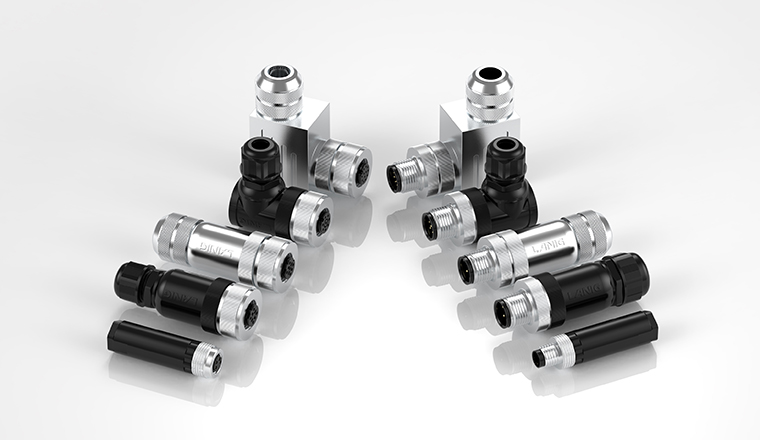

With the rise of Industry 4.0 and smart manufacturing, automation technology has become the core of modern manufacturing. In this process of intelligent transformation, sensor connectors play a vital role. As the neural hub in industrial automation systems, sensor connectors not only ensure efficient connections between devices but are also crucial for achieving precise control and data collection. Next, let's delve into the applications of sensor connectors in industrial automation and the transformations they bring.

The Role of Sensor Connectors in Industrial Automation

Sensor connectors act as interfaces that link sensors with control systems or other electronic devices. They need to provide stable signal transmission to ensure the accuracy of data and the reliability of the system. Sensor connectors allow sensors to be installed and maintained more flexibly in complex industrial environments while ensuring the integrity and efficiency of signal transmission.

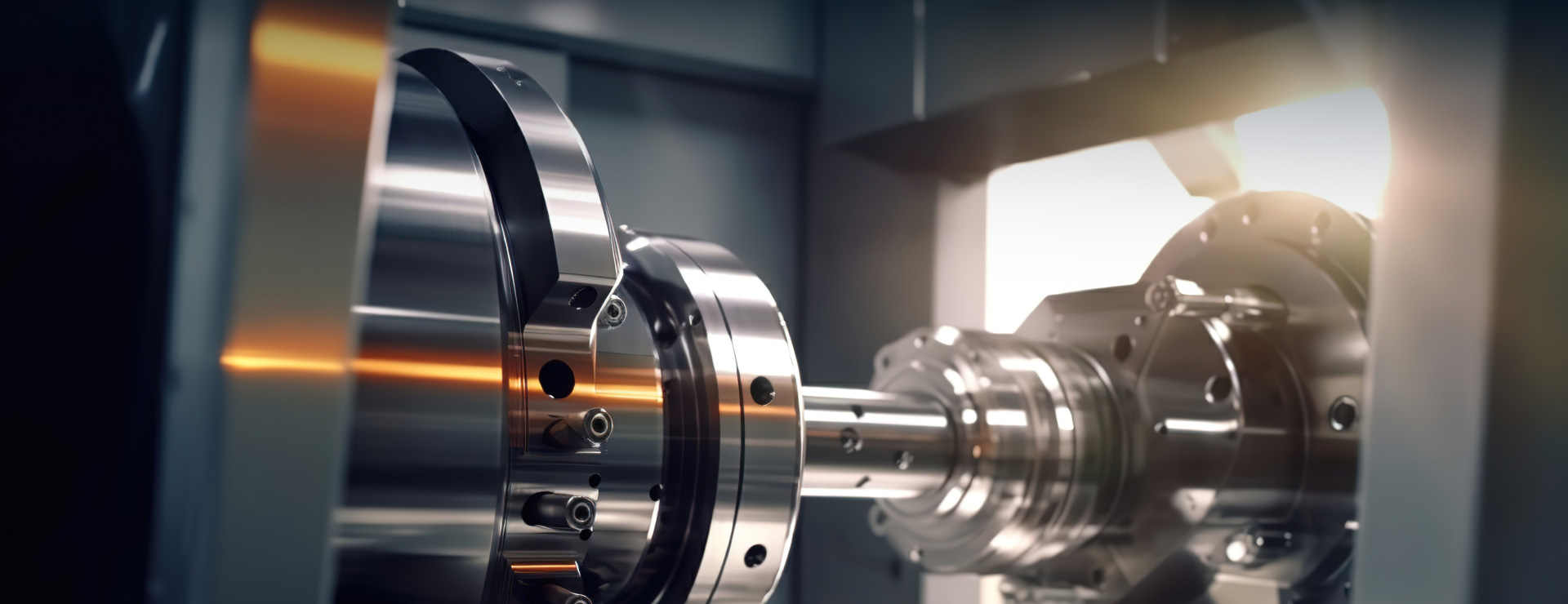

Ensuring Precise Control in Production Processes

In production lines and automated workshops, sensor connectors are used in conjunction with various sensors, such as temperature, pressure, flow, and position sensors. These sensors continuously monitor various parameters during the production process and transmit the data to the control system through the connectors. The control system then analyzes and makes decisions based on the received data, automatically adjusting the state of production equipment to ensure the stability of the production process and the consistency of product quality.

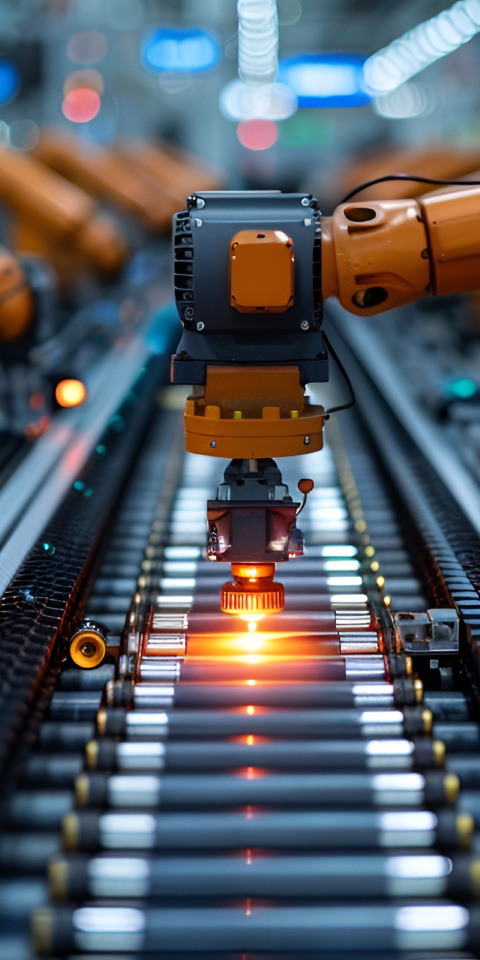

Real-Time Monitoring of Equipment Status

Sensor connectors make equipment status monitoring more convenient. By connecting various status monitoring sensors, such as vibration, speed, and current sensors, the operating conditions of the equipment can be monitored in real-time. Once an abnormality is detected, the system immediately issues an alarm and can automatically initiate safety procedures, such as slowing down or shutting down, to prevent accidents and ensure the safety of personnel and equipment.

Improving Energy Efficiency and Reducing Operating Costs

Sensor connectors are also essential for achieving energy conservation and consumption reduction in industrial automation. They are connected with energy monitoring sensors to enable real-time monitoring and control of energy consumption, helping to optimize the energy efficiency of the production process. By precisely controlling energy use, not only can energy waste be reduced, but long-term operating costs can also be lowered, achieving sustainable development.

Flexibly Meeting the Challenges of Industrial Internet

As industrial internet development progresses, the interconnectivity between devices becomes increasingly important. The flexibility and scalability of sensor connectors enable them to adapt to complex industrial network environments, connecting various smart devices and systems, meeting the requirements of the industrial internet of things for real-time data exchange and processing.

Sensor connectors are the infrastructure of industrial automation, and their importance is self-evident. They not only improve production efficiency and product quality but also provide solid technical support for the intelligent upgrade of enterprises. As technology continues to advance, sensor connectors will play an even more critical role in the field of industrial automation, driving the manufacturing industry towards a more intelligent, efficient, and environmentally friendly direction.

#Sensor Connectors #Industrial Automation #Smart Manufacturing

The registered trademark belongs to Lanig Electric (Zhejiang) Co., Ltd

The registered trademark belongs to Lanig Electric (Zhejiang) Co., Ltd