In mechanical manufacturing, sensor technology is an important link in achieving testing and automatic control. In the mechanical manufacturing testing system, it is used as an instrument positioning, and its main feature is the ability to correctly transmit and detect information of a certain form, and convert it into information of another form. Specifically, sensors refer to components or devices that have the ability to infect (or respond to) and detect certain information about the object being measured, and convert it into corresponding output signals according to certain rules. Without sensors to accurately and reliably capture and convert the raw information being tested, all correct testing and control cannot be achieved; Even the most modern electronic computers will not be able to fully perform their intended functions without accurate information (or reliable data conversion) and undistorted inputs.

In mechanical manufacturing, complex visual systems are a mature technology that can perform detailed automatic maintenance. Compared to photoelectric sensors, visual sensors give machine designers greater flexibility. Applications that used to require multiple photoelectric sensors can now use a single visual sensor to inspect multiple features. Visual sensors are able to maintain much larger areas and achieve better target position and directional flexibility in mechanical manufacturing, making them widely popular in applications that previously relied solely on photoelectric sensors. Traditionally, these applications also require expensive accessories and precise motion control that ensures the target object always appears in a unified position and posture.

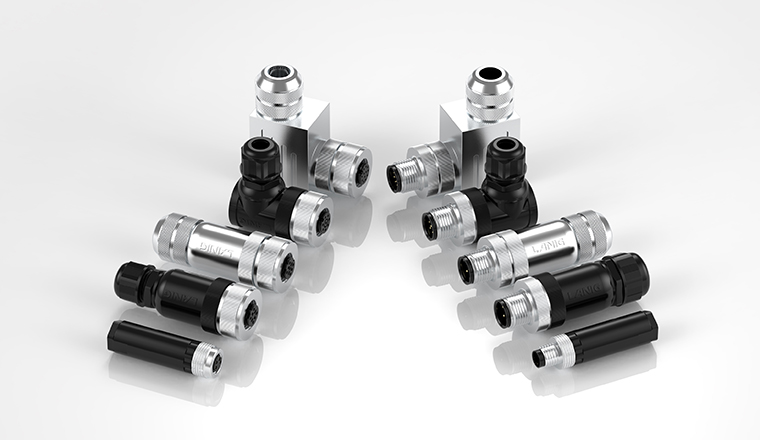

The registered trademark belongs to Lanig Electric (Zhejiang) Co., Ltd

The registered trademark belongs to Lanig Electric (Zhejiang) Co., Ltd